Drilling in oil and gas exploration invovles a lot of equipment and facilities. These equipment and facilities need to be designed very carefully,

due to the risk of hazardds to personnel, properties and enviroment. Therefore, the design of drilling system is highly regulated by local or international

codes/standards, such as API, DNV, ABS, or ASME. These codes/standards provide guidances on the design and analysis of the drilling equipment. Recently,

managed pressure drilling (MPD) and safety devices (e.g., riser gas handling), have been used extensively in onshore and offshore drilling, expecially in offshore

deepwater drilling. Design and analysis of drilling equipment require advanced understanding on codes/standards. Tau Engineering has successfully designed several

drilling equipment, such as, riser, peripheral lines, BOP, riser gas handling system, and drilling pipe.

Drilling String and Subs

Drilling string and subs experience internal/external pressure, tension, torsion, bending, and temperature loads during the operations. These multiple loads make the calulation of the stress

in the drilling string difficult by hand even though the geometry of the strings/subs is relatively simple. FEA is able to calculate the stress accurately. In particular,

the vibration of the drillpipe during the drilling might cause fatigue failure especially in the local area of the diameter transion. FEA analysis is able to find the location

and the amplitute of the possible fatigue points. API 7-1, API 5DP, API RP 7G, ISO 10424, and ISO 10407 are the relative codes for drillpipe and drill subs design.

Riser and Flange

Drilling riser provides a temporary extension of a subsea oil well to a surface drilling facility. Drilling riser experience tension, boyancy, bending, internal pressure, and

temperature loads, wave loads during operation. The wave load causes fatigue issue on the flange to pipe transition. API 16Q and ISO 13624 governs the design and analysis of the

drilling riser.

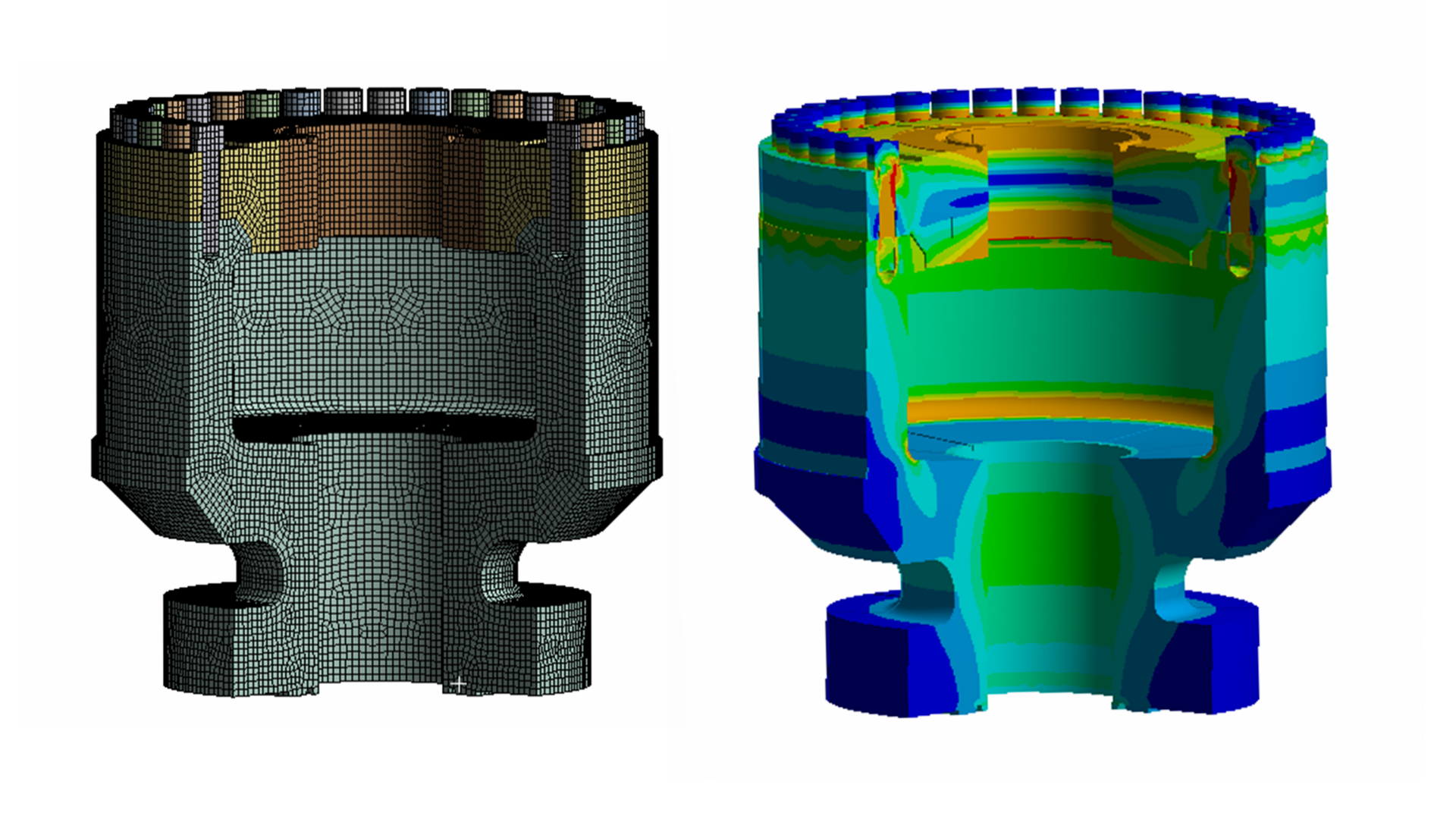

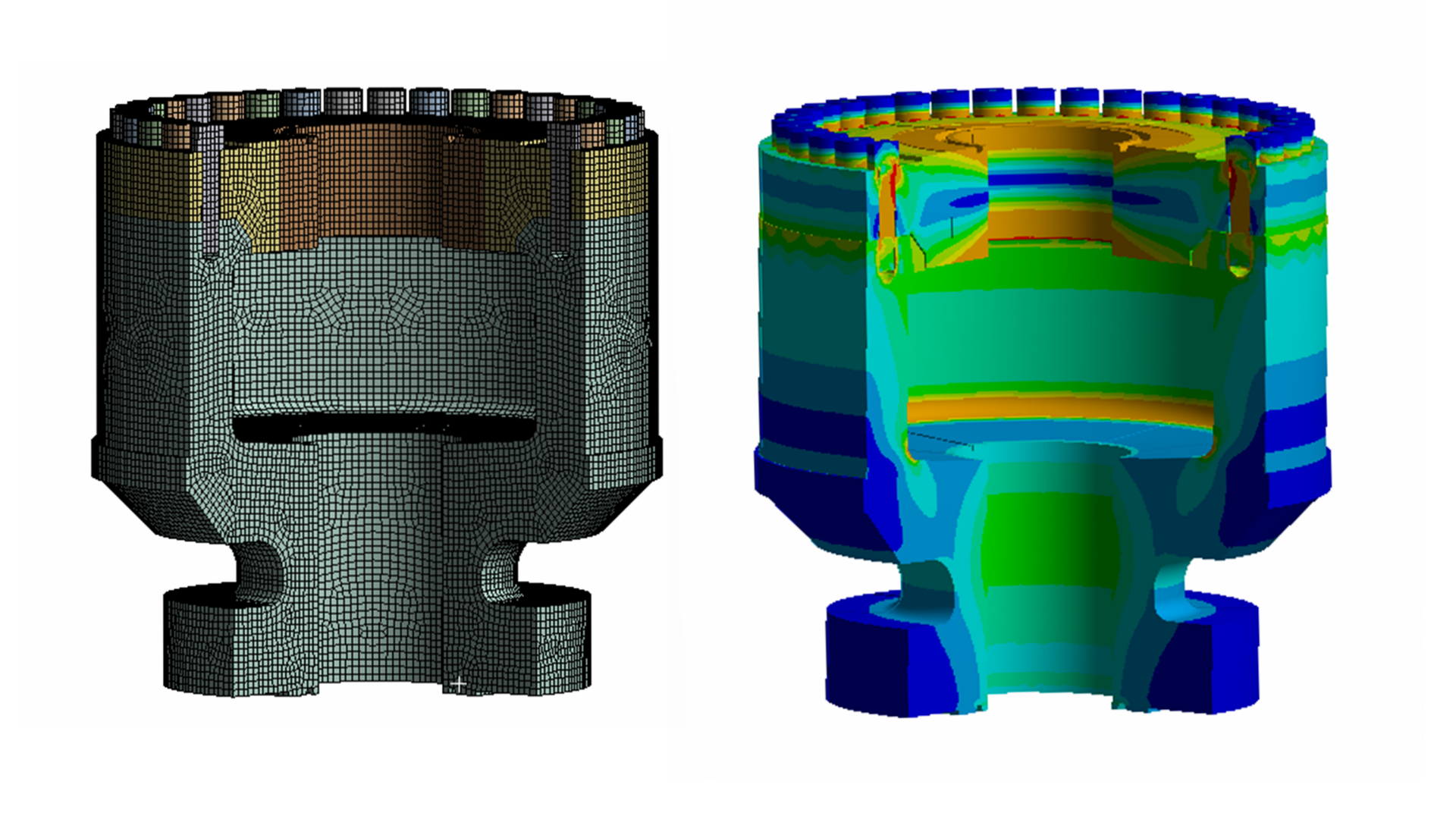

BOP Annular

BOP annular normally need to hold high pressure when a kick happens. As the secondary well control system, design of BOP need to consider high pressure and possible high

temperature. The HPHT conditions might cause new failure modes on BOP, i.e., ratcheting and creep. These new failure modes as well as the conventional failure mode

need to be assessed carefully to ensure system integrity. API 53, API 6A, API 16A and ASME BPVC codes regulate the design, manufactuing, inspection of BOP.

Other Drilling Equipment

Design and analysis of other drilling equipment also require FEA to obtain accurate stress. For example, derrick and other surface structure which require

structural analysis for design,

cementing casing and surface control piping system which require pipe stress analysis , pump/compressor which need

vibration and stress analysis.