Structural analysis addresses

analysis of the effects of loads on the structure. Tau Engineering's experienced

design/analysis

engineers provides analysis solutions, will greatly improve robustness,

cost effective, as well as safety.

Tau Engineering provides structural design/analysis services (Design to international design standard, i.e. US Design Codes, British Design Codes) as follows:

Tau Engineering provides structural design/analysis services (Design to international design standard, i.e. US Design Codes, British Design Codes) as follows:

- Offshore Structure/Onshore Structure

- Lifting Frame/Transportation Frame

- Pipe Support

- Other Mechanical Structures

- 2D/3D Modeling and Drafting

- Stress Analysis

- Vibration Analysis

- Linear/Nonlinear FEA Analysis

- Low/High Cycle Fatigue Analysis

- Linear/Nonlinear Buckling Analysis

Onshore/Offshore Structure

Structures might be designed to various limit states dependent on the operational conditions. The limit states include ultimate limit states, fatigue limit states,

accidental limit states, and serviceability limit states. Different design limits have different design loads and allowables. Weldment and bolts are the two major

connections in the structures. The structure with connections are normally complex to be analyzed by hand calculation. Advanced FEA skills are required to simulate the

response of the structure under various load conditions.

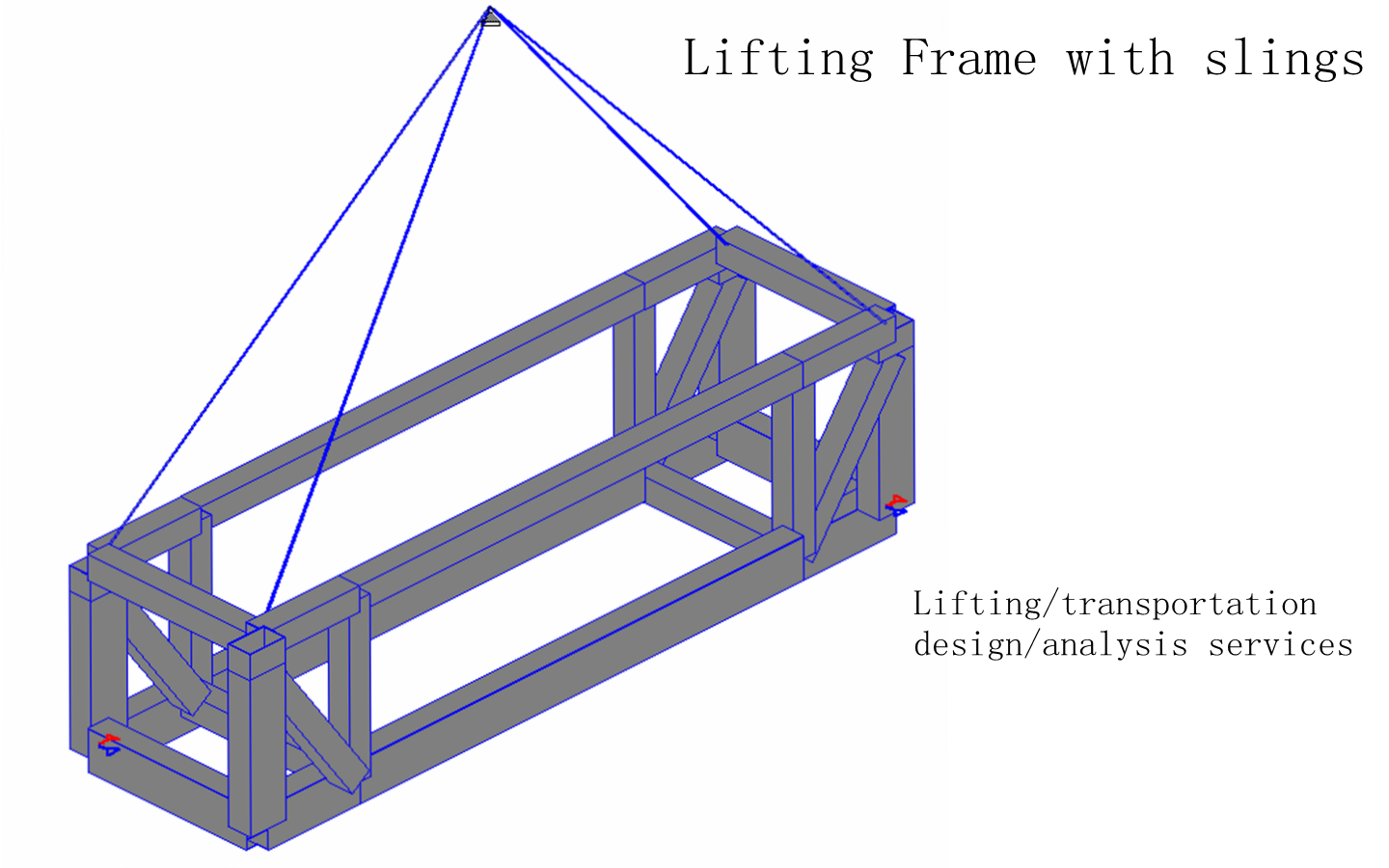

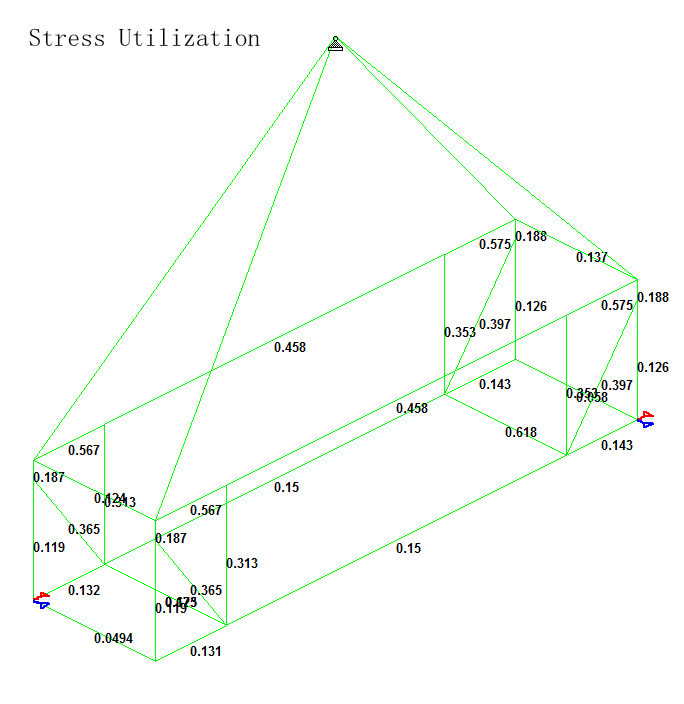

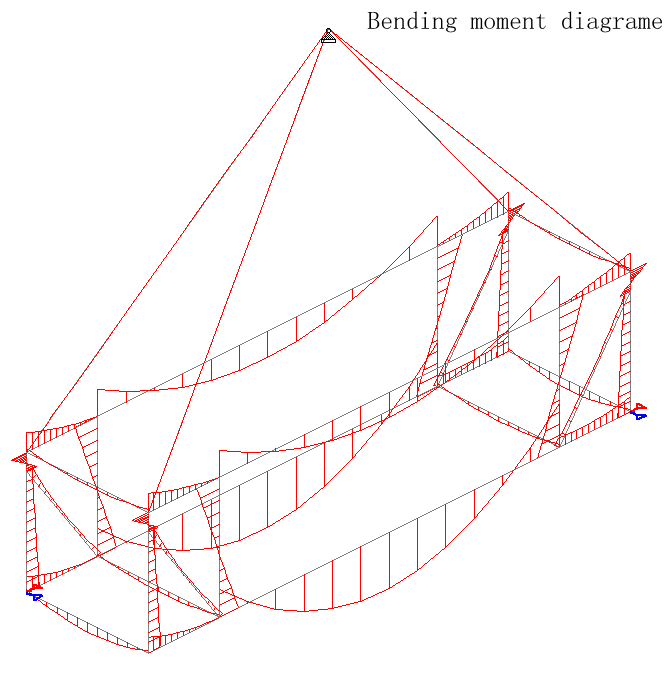

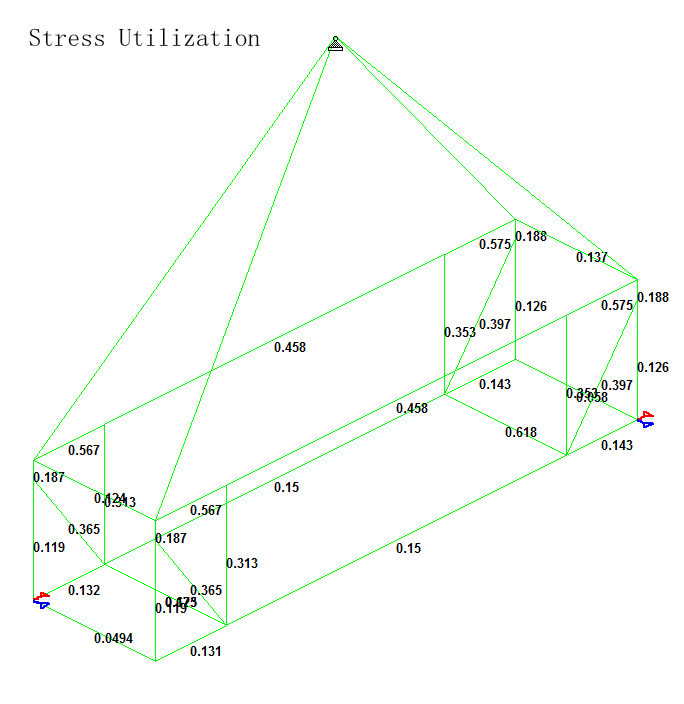

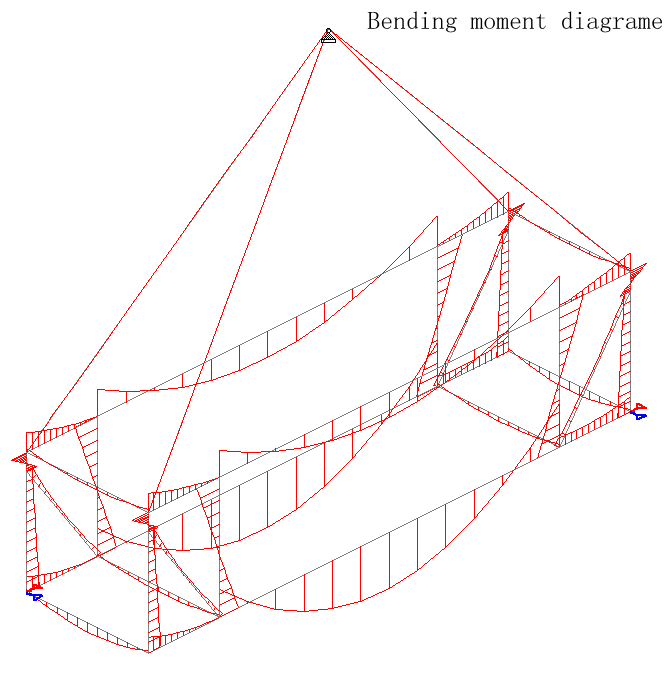

Lifting/transportation Frame

Lifting/transportation frames are applied to lifting or transporting the onshore/offshore equipment. Lifting/transportation frames shall have sufficient strength and integrity

to withstand both static and dynamic forces generated during the sea transportation. Material selection of lifting/transportation frames is also very critical based on the design

requirement. Tau Enginneering has successfully designed and deployed a few offshore lifting/transportation frames that are certificated from DNV. Below is one of the example.

Pipe support

Pipe supports are a special type of structure that used in piping system. The pipe support is an integrated part in design of the piping system.

The pipe stress analysis normally outputs the loads on the pipe supports. The structural engineers select or design the

pipe supports based on the loads and the support types (e.g., anchors, guides/clamps, hangers, U-bolts). Tau Engineering designed and engineered various

pipe supports for subsea peripheral lines, hydraulic pipes due to fluid transient loads. Below are a few exmaples.

Other Mechanical Structures

Tau Engineering is also experienced in other mechanical structures. Our engineering is able to design your mechanical products, components/structures, from

FEED, conceptual design, engineering, until testing (FAT). Tau Engineering is able to apply advanced FEA skills to ensure the mechanical integrity.

We are also able to design structure compliant to local or international codes/standards, such as, DNV, ABS or other codes.

2D/3D Modeling and Drafting

Tau Engineering provides services for 2D/3D modeling and drafting. We have experienced engineering in 2D/3D modeling and drafting.